Step 4: Problem-Solving Tools & Techniques

Assistance with the Tools: while Lean Management is all about developing a robust problem-solving culture, there are several tools that will help you develop cross-functional thinking. The tools are merely a structured means to develop a nimble, problem-solving culture.

These tools may require explanation and assistance to teach, which is where your membership comes in super handy. Please call upon the knowledge and experience of our members in the Members Directory to assist you in the application of these tools.

From experience, don't do it alone, use the decades of collective knowledge of the Network.

We are all committed to your success and looking forward to helping you!

These tools may require explanation and assistance to teach, which is where your membership comes in super handy. Please call upon the knowledge and experience of our members in the Members Directory to assist you in the application of these tools.

From experience, don't do it alone, use the decades of collective knowledge of the Network.

We are all committed to your success and looking forward to helping you!

Copyright

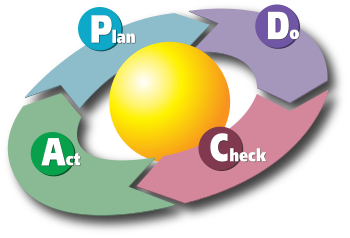

PDCA doesn't mean "Please Don't Change Anything": what does it mean to you?

|

Is this your staff?

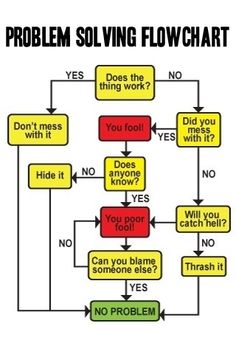

Does this seem like what happens every day at work? Do all problems end up with leadership? Why? Why? Why? What's the problem the passengers see in the video? What's the problem you see in the video? What's the real problem? Developing a problem-solving culture enables your staff to understand the real problem and to think of creative ways never to get stuck again. |

|

|

PDCA Introduction (MGH 2013) Problems come in all shapes, sizes and complexity. When staff doesn't have the basic skills to Problem-Solve, all problems explode and the Leader finds themselves overwhelmed with extinguishing brushfires. Building a true Problem-Solving culture requires incremental training starting with the basics. Have your team analyze the video to the right to determine "what's the REAL problem" we see here. Does this video or flow chart reflect the problem-solving skills of your team? If yes, it's time to develop your team.

|

|

PDCA Everyday

This step-by-step tutorial guides your staff through the PDCA process of riding a bike. Based on the works of Shewhart and Deming, this simple but powerful process lays the foundation for developing an army of problem-solvers in your staff. Start small and stay small; ask your staff "what sucks about this process" and watch the thinking wheels turn. The PDCA process will help them find the best solutions to the tiny aging problems they face every day. Start small and stay small; don't try to solve world hunger or world peace; you're doomed from the start. |

| ||||||

5-Whys and 1-How: a great place to start your team thinking...

The Jefferson Memorial

Corny, we know, but this is a fun way for your staff to see how the 5-Whys cascade.

We advise that your staff watch it twice and capture the "causes" on the "5-Why" template as they hear them, then work together to agree on what they heard.

No points for fashion violations.

Corny, we know, but this is a fun way for your staff to see how the 5-Whys cascade.

We advise that your staff watch it twice and capture the "causes" on the "5-Why" template as they hear them, then work together to agree on what they heard.

No points for fashion violations.

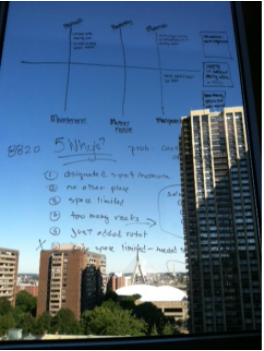

5-Whys (MGH 2013)

The first step in developing Team Problem-Solving skills is in practicing the "5-Whys, 1-How" technique. The Fishbone tutorial addresses the method to guide the linear 5-Why discussion that often uncovers other problems. Attached are useful tools for developing the 5-Why skills with your teams.

The first step in developing Team Problem-Solving skills is in practicing the "5-Whys, 1-How" technique. The Fishbone tutorial addresses the method to guide the linear 5-Why discussion that often uncovers other problems. Attached are useful tools for developing the 5-Why skills with your teams.

5-Why Template

The 5-Whys are an easy technique used to introduce your staff to understanding how causes cascade and breaks their habit of reacting to problems.

While it's easy to follow, one person's perspective to "why" can be very different from another's. This s where discussion can be so important and highlights the lack of standardization.

The 5-Whys are an easy technique used to introduce your staff to understanding how causes cascade and breaks their habit of reacting to problems.

While it's easy to follow, one person's perspective to "why" can be very different from another's. This s where discussion can be so important and highlights the lack of standardization.

| 5why_template.ppt | |

| File Size: | 22 kb |

| File Type: | ppt |

5-Why Vivarium Simulation

This s a useful hypothetical simulation that walks your staff through the various levels of causation.

In this case, there are "6-Whys" that are needed to identify root cause.

Validation is always important by reversing the order from the bottom up. "This causes this to happen, which causes this which causes this..." etc.

Try it with your staff.

This s a useful hypothetical simulation that walks your staff through the various levels of causation.

In this case, there are "6-Whys" that are needed to identify root cause.

Validation is always important by reversing the order from the bottom up. "This causes this to happen, which causes this which causes this..." etc.

Try it with your staff.

| photo__15_.jpg | |

| File Size: | 82 kb |

| File Type: | jpg |

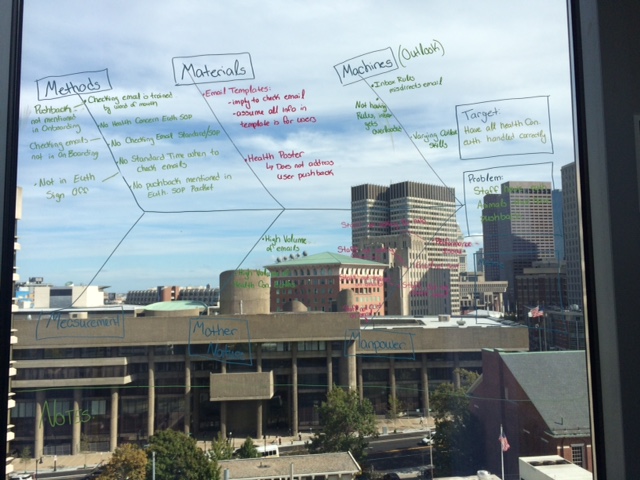

Fishbone Diagraming for Vivarium Staff

Fishbone Diagramming (MGH 2013) The 5-Whys is a highly effective exercise for single-cause problems, but most problems have multiple causes, which makes the Fishbone Diagram the next tool in their toolkit. The Fishbone enables the Team to categorize the causes to better identify effective countermeasures to eliminate those causes. The material found here is designed for a non-threatening introduction to deeper team problem-solving.

Instruction Packet

These instructions guide the teacher through the steps in teaching the use of the Fishbone tool.

While used in Kaizens and Problem-Solving routines, the Fishbone diagram exercise should be organic, inclusive and spontaneous.

Everyone is asked to participate in identifying causes and root causes to a problem.

These instructions guide the teacher through the steps in teaching the use of the Fishbone tool.

While used in Kaizens and Problem-Solving routines, the Fishbone diagram exercise should be organic, inclusive and spontaneous.

Everyone is asked to participate in identifying causes and root causes to a problem.

| fishbone_tool_kit.ppt | |

| File Size: | 3238 kb |

| File Type: | ppt |

Fishbone Template

The Fishbone Worksheet looks intimidating, but it structures the team discussion and clusters causes into categories.

The Fishbone Worksheet looks intimidating, but it structures the team discussion and clusters causes into categories.

|

| ||||||||||||

Team-Based Problem-Solving Scenarios: developing team problem-solving capability

Problems large and small are often overlooked just to keep operations moving. The toxic side of ignoring problems is that they often come back to haunt the team time after time after time. Choosing the first solution is often the wrong solution and can cause more problems downstream.

Getting your entire staff acclimated to the discipline of seeing and addressing problems together allows different perspectives to add to a quality and often reliable solution.

Team-Based Scenarios (2016; Tummala. OMRF)

The goal of the scenarios below is to leverage multiple perspectives to solve vivarium-based problems. We suggest that you start this exercise by using an example that everyone is familiar with, such as the "Toast" video on the "Waste" page or the "Lucy Chocolate Factory" video on the "Leadership Academy Page".

Feel free to modify the scenarios to reflect your operation and learning needs.

Walk your team through the example using the various steps used in Problem-Solving without getting into detail:

Have each team report out their 3 solutions and discuss as a group on why they are different or the same between groups.

Getting your entire staff acclimated to the discipline of seeing and addressing problems together allows different perspectives to add to a quality and often reliable solution.

Team-Based Scenarios (2016; Tummala. OMRF)

The goal of the scenarios below is to leverage multiple perspectives to solve vivarium-based problems. We suggest that you start this exercise by using an example that everyone is familiar with, such as the "Toast" video on the "Waste" page or the "Lucy Chocolate Factory" video on the "Leadership Academy Page".

Feel free to modify the scenarios to reflect your operation and learning needs.

Walk your team through the example using the various steps used in Problem-Solving without getting into detail:

- "What's the problem?"

- "What's the Current Condition?"

- "What's the Target Condition?"

- "What's the root cause or what's getting in our way?"

- "What are some ways we can brainstorm solutions to make the problem never happen again?"

- "What are our best solutions?"

- "How can we check that it works going forward?"

Have each team report out their 3 solutions and discuss as a group on why they are different or the same between groups.

|

|

| ||||||||||||||||||

|

|

| ||||||||||||||||||

|

| ||||||||||||

Mighty Mouse Case Study

This is an easy-peasy case study used to introduce the Fishbone technique to new technicians.

The new employees work in a group to identify the problem, the causes of the problem and the categories that the causes cluster into.

The final stage is for them to brainstorm potential countermeasures and to prioritize them on an Affinity Diagram to determine what changes they can implement to make the problem go away.

This is an easy-peasy case study used to introduce the Fishbone technique to new technicians.

The new employees work in a group to identify the problem, the causes of the problem and the categories that the causes cluster into.

The final stage is for them to brainstorm potential countermeasures and to prioritize them on an Affinity Diagram to determine what changes they can implement to make the problem go away.

| Case Study Mighty Mouse | |

| File Size: | 21 kb |

| File Type: | doc |

Team-Based Problem Solving

Problem-Solving Sheet (MGH 2013)

Teaching structured problem-solving to your staff can be a daunting and scary exercise. Toyota developed the "A3" problem-solving tool that can still be intimidating to users. Technicians were given free license to develop a structured Problem Solving sheet of their own, and this was the result. Feel free to edit for your own needs.

Teaching structured problem-solving to your staff can be a daunting and scary exercise. Toyota developed the "A3" problem-solving tool that can still be intimidating to users. Technicians were given free license to develop a structured Problem Solving sheet of their own, and this was the result. Feel free to edit for your own needs.

Guidelines

This instructional document was designed by technicians for technicians to outline the steps to complete the Problem-Solving Sheet (attached).

The Problem-Solving Sheet flows in the same way as the Toyota A3 (also attached here).

By allowing your staf to create their own Problem-Solving sheet using proven methodology, they become the architects of their own learning.

This instructional document was designed by technicians for technicians to outline the steps to complete the Problem-Solving Sheet (attached).

The Problem-Solving Sheet flows in the same way as the Toyota A3 (also attached here).

By allowing your staf to create their own Problem-Solving sheet using proven methodology, they become the architects of their own learning.

| problem_solving_guidelines | |

| File Size: | 469 kb |

| File Type: | pptx |

Problem-Solving Sheet

Based on the structure of the Toyota A3, technicians decided to create their own Problem-Solving Sheet that would work for them.

If your staff is intimidated by the A3, challenge your staff to create their own Problem-solving sheet or storyboard using the Toyota methodology.

Leadership's role is to coach the team through frequent check-ins to understand their thinking and to avoid rushing to solutions.

Based on the structure of the Toyota A3, technicians decided to create their own Problem-Solving Sheet that would work for them.

If your staff is intimidated by the A3, challenge your staff to create their own Problem-solving sheet or storyboard using the Toyota methodology.

Leadership's role is to coach the team through frequent check-ins to understand their thinking and to avoid rushing to solutions.

| problem_solving_sheet | |

| File Size: | 256 kb |

| File Type: | ppt |

Toyota "A3"

This is the classic Toyota A3 Problem-Solving format.

It's easy to use and should be a pencil-to-paper living, unpolished document used in real-time by the team at the point of the problem.

This is the classic Toyota A3 Problem-Solving format.

It's easy to use and should be a pencil-to-paper living, unpolished document used in real-time by the team at the point of the problem.

| ccm_a3.ppt | |

| File Size: | 224 kb |

| File Type: | ppt |

5S Training Module (2014 Murli & Associates)

| five_s_training_module_rev_f.ppt | |

| File Size: | 8314 kb |

| File Type: | ppt |

Lean Terminology: "what the heck is a Kanban?"

|

Terminology Handbook V1.0

Lean Management was based on the tools and techniques developed over 50 years by Toyota in Japan. Many of the terms used in Lean organizations retain their Japanese origins and words; some are not easily translated into English. Many organizations have replaced the Japanese terms with English terms, something we strongly advise you to do for ease of learning. These open-source handbooks are meant for reference only; take what you need and leave the rest behind. Modify as you see fit. Refer to the "Visual Control Legend" above for icon management. Please share your revisions with the VOE-Network community by sending them to: [email protected] |

| ||||||||||||||

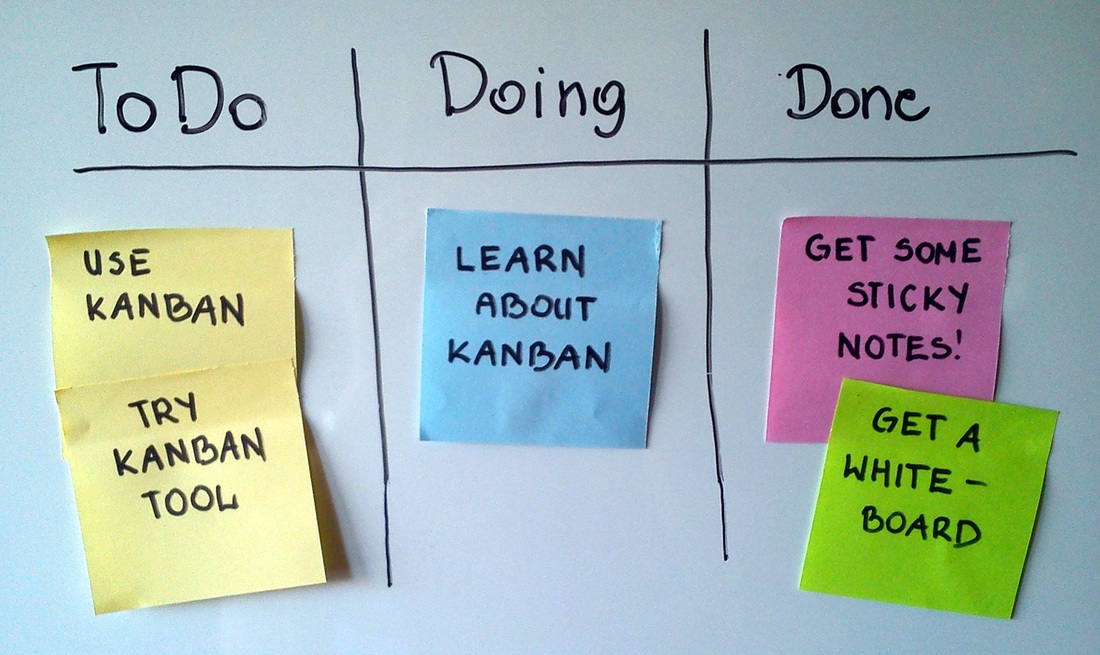

Kanban Techniques

|

"Kanban" is an inventory-control system to control the supply chain. Developed at Toyota, kanban is used to "pull" material when needed to improve efficiency or to communicate status or next steps.

Based on the American supermarket model of replenishing only what is needed to fill a shelf when the critical "low point" is reached, Kanban is gauged by consumer demand, available resources or time it takes to reorder. Once staff understands how Kanban supports them, they will eagerly develop systems that will make materal replenishment seamless. |

View Here

|

Hazmat Encounter: What would you do?

|

What would they do?

Sometimes assumptions are made and communication missed that may expose technicians to a hazardous chemical encounter. While your processes and equipment may differ, this video may stimulate discussion among staff members to a) identify the problem, b) map out the current state, c) identify root causes and d) brainstorm potential countermeasures toward developing standardized response procedures as a team. Make up your own scenario and share it with our members! |

|

How can we get help?

|

"How do you eat an elephant?

...one bite at a time." Tools can be intimidating and videos can only show so much. We want to help you succeed, it's as simple as that. Contact us and we will help to find the answer or will work to get you direct assistance from experienced practitioners. Sends us an email at: [email protected] |