Assistance with the Tools: while Lean Management is all about developing a robust problem-solving culture, there are several tools that will help you develop cross-functional thinking. The tools are merely a structured means to develop a nimble, problem-solving culture.

These tools may require explanation and assistance to teach, which is where your membership comes in super handy. Please call upon the knowledge and experience of our members in the Members Directory to assist you in the application of these tools.

From experience, don't do it alone, use the decades of collective knowledge of the Network.

We are all committed to your success and looking forward to helping you!

These tools may require explanation and assistance to teach, which is where your membership comes in super handy. Please call upon the knowledge and experience of our members in the Members Directory to assist you in the application of these tools.

From experience, don't do it alone, use the decades of collective knowledge of the Network.

We are all committed to your success and looking forward to helping you!

Step 3: Understanding "Waste"

|

"Waste" is a fundamental concept that makes Continuous Improvement so attractive to organizations that wish to improve operations.

Once we understand the concepts of "Value Added" and "Non-Value Added" relative to our customer, we begin to understand that waste is the insidious zombie that sucks the life out of operational efficiency. Understanding that every unintentional action, inaction, or extra step in a process that gets in the way of delivering Value to our customers must be considered waste and must be eliminated. Ask yourself: "If the customer was aware of all the waste in a process, would they gladly pay for it?" "Would you pay for it if you knew about it?" ...If you wouldn't want to pay for it, then it is our responsibility to eliminate it for our customers... |

Copyright

Identifying Waste: "the greatest productivity thief in your organization"

"But it's the way we've always done it"

Probably the most costly 8 words in Vivarium Operations.

It's all in the data:

Time-motion studies conducted by animal technicians in various vivariums have revealed that between 40% and 60% of technician activity in a vivarium are unnecessary and wasteful; mainly due to bad or no structured processes...paying staff to do little that advances research.

Waste is a hidden enemy that technicians battle every day. Waste causes staff stress and turnover. Managers try to budget for waste. and guess who ultimately pays for all the waste in your system? The customers.

Once your staff starts to ask "Why are we doing it this way?" they start to "see" all the places where they are doing work unnecessarily and will want to change things and eliminate waste, a very good thing.

Caveat: Leadership's role it to teach your staff to identify and eliminate Waste, but always from the customer's perspective.

Always be mindful of eliminating those "wasteful" steps or items that may reduce the quality or the service to the customer. If the Waste potentially affects the customer in a negative way or if the Waste impacts other roles or the quality of service in a negative way, that's when you MUST involve the customer and other associated roles to arrive at the best solution to remediate waste.

Probably the most costly 8 words in Vivarium Operations.

It's all in the data:

Time-motion studies conducted by animal technicians in various vivariums have revealed that between 40% and 60% of technician activity in a vivarium are unnecessary and wasteful; mainly due to bad or no structured processes...paying staff to do little that advances research.

Waste is a hidden enemy that technicians battle every day. Waste causes staff stress and turnover. Managers try to budget for waste. and guess who ultimately pays for all the waste in your system? The customers.

Once your staff starts to ask "Why are we doing it this way?" they start to "see" all the places where they are doing work unnecessarily and will want to change things and eliminate waste, a very good thing.

Caveat: Leadership's role it to teach your staff to identify and eliminate Waste, but always from the customer's perspective.

Always be mindful of eliminating those "wasteful" steps or items that may reduce the quality or the service to the customer. If the Waste potentially affects the customer in a negative way or if the Waste impacts other roles or the quality of service in a negative way, that's when you MUST involve the customer and other associated roles to arrive at the best solution to remediate waste.

|

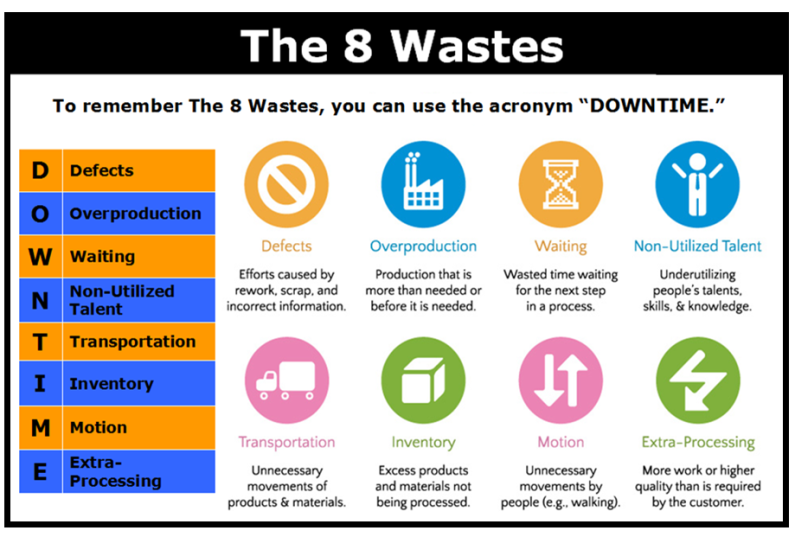

8-Waste Visual Control (MGH 2016) This visual control (suitable for framing) references each of the 8 Wastes that plague our workdays. Review this before viewing the Toast Videos below.

8-Waste Crime Scene Worksheet (MGH 2014) This tool enables staff to identify any of the 8-Wastes when they see it.

This sheet is useful for Gemba Walks (or the Scene of the Crime) and should be used while viewing the "Toast videos" below. |

| ||||||||||||

Identifying (Seeing) Waste: The infamous "Toast Video"

Toast Video Training Exercise Part 1 (GBMP 2013)

This world-famous video develops workers' skills to "see" waste in everyday situations.

The concepts demonstrated in this video are easily transferable to the vivarium, to husbandry, to cage wash, to the office, to IACUC, to computer files and to your home.

The importance of workplace organization can not be underestimated when trying to deliver value to the customer.

Assignment:

First, have your staff review the "8 Waste" Master slide together.

Next, using the "Wastewalk Crime Scene" tool above, have them identify the wastes while they view the video.

They can "call it out loud" while the facilitator records them or they can record it on the Wastewalk form.

Next, as a team, brainstorm ways to remove the many wastes in the process to make it easier (potential countermeasures).

This world-famous video develops workers' skills to "see" waste in everyday situations.

The concepts demonstrated in this video are easily transferable to the vivarium, to husbandry, to cage wash, to the office, to IACUC, to computer files and to your home.

The importance of workplace organization can not be underestimated when trying to deliver value to the customer.

Assignment:

First, have your staff review the "8 Waste" Master slide together.

Next, using the "Wastewalk Crime Scene" tool above, have them identify the wastes while they view the video.

They can "call it out loud" while the facilitator records them or they can record it on the Wastewalk form.

Next, as a team, brainstorm ways to remove the many wastes in the process to make it easier (potential countermeasures).

Toast Video Training Exercise Part 2 (GBMP 2013)

Part 1 would not be complete without Part 2.

While Part 1 is painful to watch and may represent our every workday, Part 2 represents how continuous improvement can radically affect process outcomes.

Note that in Part 1, the ultimate waste was the result of not knowing what the customer clearly wanted in the very beginning. The entire process created scrap; the worker was rejected, the product was trashed, and the customer didn't get served what they wanted when they wanted it.

Part 2 involves the customer as a stakeholder from the start and incorporates all the improvements that your staff identified in Part 1.

Thank you to the GBMP for allowing the VOE-Network to share this video with our members.

Assignment:

Have your team identify the improvements they "see" that have been implemented in the process.

Have them discuss the impact of the new process.

Ask them: what other opportunities for improvements do you "see" that can make this process even better.

Their answers demonstrate the fundamentals of Continuous Improvement: once you achieve a "better way", it's easy to start looking for the next "better way".

Part 1 would not be complete without Part 2.

While Part 1 is painful to watch and may represent our every workday, Part 2 represents how continuous improvement can radically affect process outcomes.

Note that in Part 1, the ultimate waste was the result of not knowing what the customer clearly wanted in the very beginning. The entire process created scrap; the worker was rejected, the product was trashed, and the customer didn't get served what they wanted when they wanted it.

Part 2 involves the customer as a stakeholder from the start and incorporates all the improvements that your staff identified in Part 1.

Thank you to the GBMP for allowing the VOE-Network to share this video with our members.

Assignment:

Have your team identify the improvements they "see" that have been implemented in the process.

Have them discuss the impact of the new process.

Ask them: what other opportunities for improvements do you "see" that can make this process even better.

Their answers demonstrate the fundamentals of Continuous Improvement: once you achieve a "better way", it's easy to start looking for the next "better way".

How can we get help?

|

"How do you eat an elephant?

...one bite at a time." Tools can be intimidating and videos can only show so much. We want to help you succeed, it's as simple as that. Contact us and we will help to find the answer or will work to get you direct assistance from experienced practitioners. Sends us an email at: [email protected] |