Assistance with the Tools: while Lean Management is all about developing a robust problem-solving culture, there are several tools that will help you develop cross-functional thinking. The tools are merely a structured means to develop a nimble, problem-solving culture.

These tools may require explanation and assistance to teach, which is where your membership comes in super handy.

Please call upon the knowledge and experience of our members in the Members Directory to assist you in the application of these tools.

From experience, don't do it alone, use the decades of collective knowledge of the Network.

We are all committed to your success and looking forward to helping you!

These tools may require explanation and assistance to teach, which is where your membership comes in super handy.

Please call upon the knowledge and experience of our members in the Members Directory to assist you in the application of these tools.

From experience, don't do it alone, use the decades of collective knowledge of the Network.

We are all committed to your success and looking forward to helping you!

Step 2: Workplace Organization

"...the best activity to kick-off your operations and administrative staff on their Continuous Improvement journey..." VOE-Network Director

Let them take charge

Empowering your staff to organize their workplace so that it unconditionally supports their work will provide them with the confidence that

This team-based exercise below (5S Numbers Game) stimulates group discussion as to what they collectively need to succeed in the workplace, what is getting in their way and develops a social consciousness of how the workplace supports both themselves and their peers.

Let them take charge

Empowering your staff to organize their workplace so that it unconditionally supports their work will provide them with the confidence that

- "workplace organization is critical to efficient operations",

- "their voices count" and

- "we can all do it better".

This team-based exercise below (5S Numbers Game) stimulates group discussion as to what they collectively need to succeed in the workplace, what is getting in their way and develops a social consciousness of how the workplace supports both themselves and their peers.

Copyright

Using the 5S method to achieve workplace organization

Full credit is given to "Superteams.com" for this version of this powerful exercise.

5S Numbers Game

|

The 5S Numbers Game is an easy-to-facilitate simulation that clearly and quickly demonstrates the power of workplace organization. Through this simulation, your staff will understand how workplace clutter, information clutter and daily obstacles affects their ability to perform their job efficiently.

Teams progress from the "agony of defeat" in the beginning of the exercise to the "joy of success" at the end. Your staff will experience the emotional roller coaster caused by unnecessary obstacles; no wonder they feel exhausted and frustrated at the end of the day. Now they can change that. Once they complete this exercise, ask them where they want to focus their efforts to organize first. Always measure the "Before" and the "After" in simple units of time, footsteps, bending, trips, de-gowning, quantity, etc. They will see the immediate impact of their improvements; challenge them where they want to focus next... |

|

| ||||||||||||

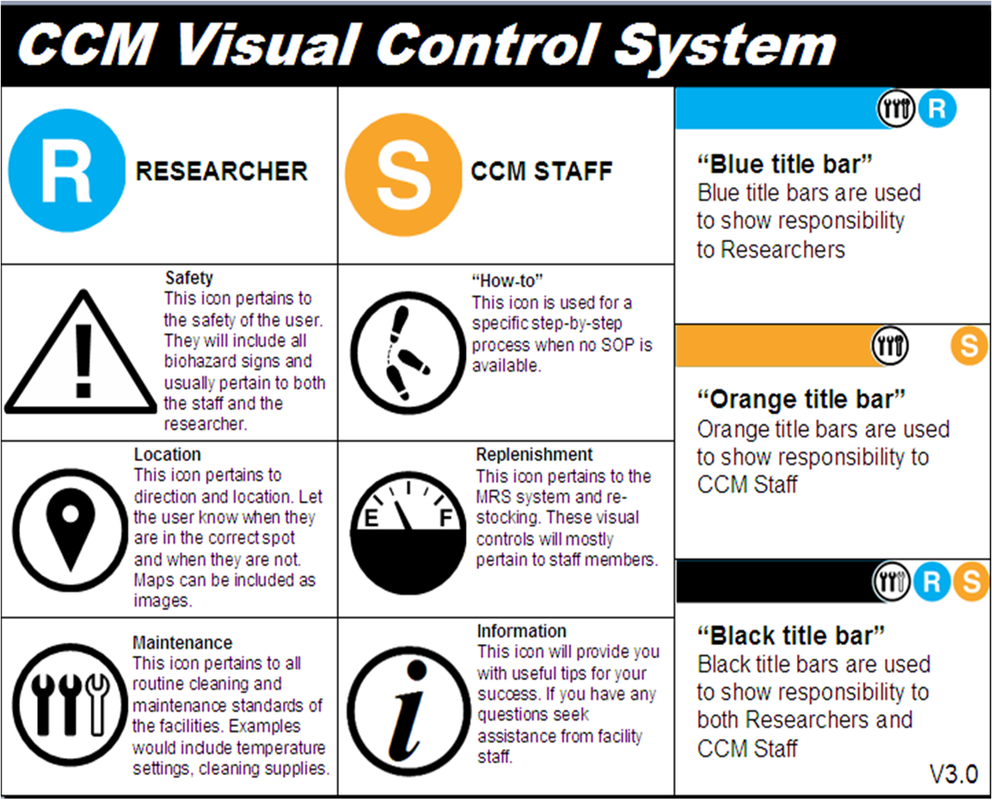

Visual Control Legend: "What is expected of me and what is expected of the PI?"

|

Visual Control Legend (MGH 2014) In a collaboration with the Art Institute of Boston, MGH challenged designers to develop a visual lexicon to help staff and customers understand what is expected of them 24 hours a day. This system makes the workplace intuitive and helps the multi-lingual investigators by answering questions before they are asked.

Lean allows us to shamelessly steal from each other. Variations of this system has been adopted by vivaria around the world. |

| |||||||||||||

Workplace Organization and Visual Workplace (McGill 2016) This is a basic instructional video on how to apply the "5S" technique to achieve workplace organization and the use of visual management.

"Tolerance Buildup"

Simple approaches are offered to solve often ignored problems. In a work setting, we often tolerate disorganization as the norm.

"Pebbles in your shoe"

When given the chance, teams can quickly identify the things that irritate them and add no value to the process. Conversely, teams will gladly identify those things they need to accomplish their tasks in an efficient way; the "ideal state" of the workplace.

The real learning comes when the teams design the HOW to maintain the "ideal state" so that it supports both their work and the investigators using the work space.

"Tolerance Buildup"

Simple approaches are offered to solve often ignored problems. In a work setting, we often tolerate disorganization as the norm.

"Pebbles in your shoe"

When given the chance, teams can quickly identify the things that irritate them and add no value to the process. Conversely, teams will gladly identify those things they need to accomplish their tasks in an efficient way; the "ideal state" of the workplace.

The real learning comes when the teams design the HOW to maintain the "ideal state" so that it supports both their work and the investigators using the work space.

| voe-mcgill_university-20160217.mp4 | |

| File Size: | 28921 kb |

| File Type: | mp4 |

Visual Workplace: "How are they doing? How do I know?"

|

The Visual Workplace at McGill University (2016 Jarrod Nichol CLSSBB)

The US Bureau of Labor Statistics clearly demonstrate that as worker's productive decline, unit labor costs rise by significant factors. http://www.bls.gov/lpc/ Lost worker productivity has a direct correlation to employee morale and a poorly designed workplace. The Lean community estimates that worker value-added activity can be as low as 5% in an organization that does not support the work! In this video, Lean Sensei Jarrod Nichol walks us through the steps that develop workplace organization and the social contracts that support the work in a vivarium. |

Way too complex? (we know)

This is a sample worksheet that helps define the criteria and to train the eye to "see" what a highly-organized and intuitive workplace could look like. Perfection is the enemy of the good; we don't advocate for perfection, only the deeper understanding that the 5S questions prompt. Understanding "why" each level is important enables your team to see the advantages of applying 5S to everything.

A Simpler Worksheet for Scoring 5S Workplace Organization

|

The Visual Workplace and Workplace Organization in the Vivarium at McGill University (2016 Jarrod Nichol CLSSB)

5S Training Module (2014 Murli & Associates)

| ||||||||||||||||||

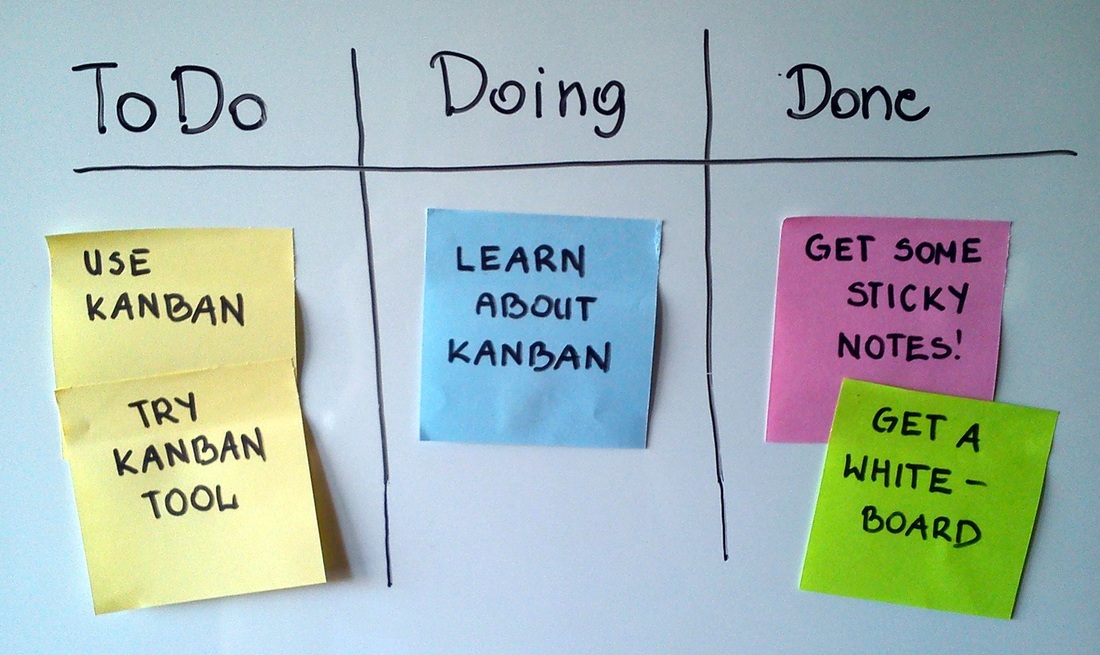

Kanban Techniques

"Kanban" is a simple inventory-control system to control the supply chain that supports a team, an entire facility or an Admin group. Developed at Toyota, kanban is a simple system used to "pull" material only when needed to improve efficiency, to communicate status or to signal next steps needed to work uninterrupted.

Based on the American supermarket model of replenishing only what is needed to fill a shelf when the critical "low point" is reached by the customer removing product, Kanban is always gauged by consumer demand, by the available resources and/or the time it takes to reorder.

Once the staff understands how the basic rules of Kanban supports them in their daily work, they will eagerly develop systems that will make material replenishment seamless and mindless.

The next big leap to automatic material replenishment is to involve your Feed & Bedding vendor, the PPE Vendor and other vendors to design a system monitored by the vendor and makes them a partner in your operations. See the "Vendor Partnerships" module for more information.

Based on the American supermarket model of replenishing only what is needed to fill a shelf when the critical "low point" is reached by the customer removing product, Kanban is always gauged by consumer demand, by the available resources and/or the time it takes to reorder.

Once the staff understands how the basic rules of Kanban supports them in their daily work, they will eagerly develop systems that will make material replenishment seamless and mindless.

The next big leap to automatic material replenishment is to involve your Feed & Bedding vendor, the PPE Vendor and other vendors to design a system monitored by the vendor and makes them a partner in your operations. See the "Vendor Partnerships" module for more information.

How can we get help?

|

"How do you eat an elephant?

...one bite at a time." Tools can be intimidating and videos can only show so much. We want to help you succeed, it's as simple as that. Contact us and we will help to find the answer or will work to get you direct assistance from experienced practitioners. Sends us an email at: [email protected] |