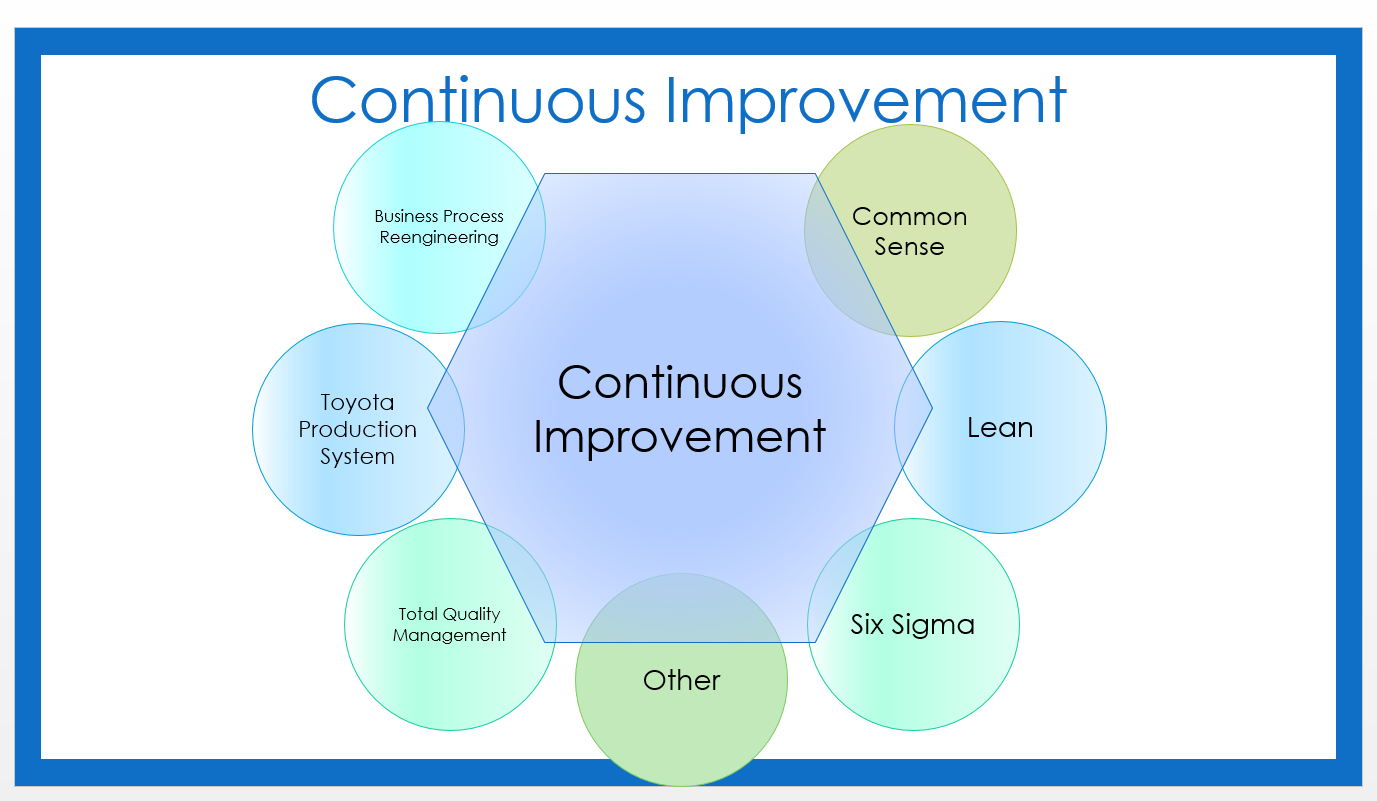

Continuous Improvement Models

Continuous Improvement is more than just tools, it's a culture whereby everyone in your organization strives for perfection. There are several popular methodologies which can help you on your journey of establishing a problem-solving culture. Regardless of which Continuous Improvement model you decide to follow, one key component is that you should never go it alone. The Vivarium Operational Excellent Network features decades of collective knowledge in Process Improvement. As the slogan says 'We're All in this Together,' and that's especially true when starting out and deciding which Continuous Improvement model to follow.

Each of the methods you see in the image above make up the global Continuous Improvement effort. There is no 'one size fits all' approach to Continuous Improvement. You need to determine what works well for your institution. Most people are surprised to see Common Sense as one of the building blocks for Continuous Improvement, but it's absolutely part every methodology. Structured Common Sense led to the creation of two of the more popular methodologies we will be look at below.

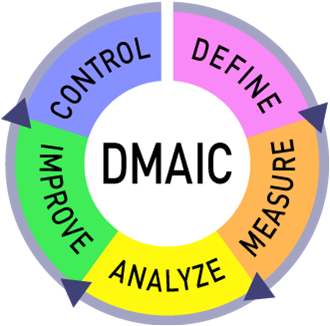

D-M-A-I-C

|

The D.M.A.I.C. system originates from Six Sigma, and is an acronym for Define, Measure, Analyze, Improve, and Control. This structured approach to data-driven Continuous Improvement is extremely popular in the world of Process Improvement. It isn't exclusive to Six Sigma either, and today is used in many organizations that run a purely Lean program.

The benefits of the D.M.A.I.C. model include not only changing the culture to one of problem-solving, but also a culture that strives on data collection. For a detailed explanation of how the D.M.A.I.C. works in a Vivarium settings, click here. |

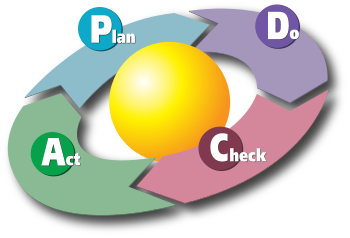

P-D-C-A

|

The P.D.C.A. cycle originates from the Toyota Production System and is also referred to as the Deming Wheel or Deming Cycle, named after its originator, W. Edwards Deming. The acronym stands for Plan, Do, Check, and Act and is often used in Lean Process Improvement organizations.

The benefits of the P.D.C.A. cycle include a more streamlined approach to Process Improvement and a focus on problem-solving. Many organizations enjoy the more simplistic approach the P.D.C.A. cycle offers. For a detailed explanation of how the P.D.C.A. model works in a Vivarium settings, click here. |

How Can We Help?

|

"How do you eat an elephant?

...one bite at a time." Tools and concepts can be intimidating, and videos can only show so much. We want to help you get started on the right foot, and be as successful as possible! Contact us and we will do our absolute best to assist in any way possible, and put you in direct contact with an experienced Continuous Improvement practitioner. Sends us an email at: [email protected] |